Compared to hardening furnaces on the market

Our machines can optimise production consumption by up to 100 kWh, whereas the most common tempering furnaces on the market consume up to three times that amount.

MAZAROPPI VALUES

We are not afraid of the new or the unknown because we create machinery capable of opening up new ground, enabling our customers to achieve tangible benefits they thought were impossible in terms of:

- Quality of the final product

- Guaranteed savings on energy consumption

- Higher Profits

- Zero unproductive costs

We dare to think outside the box to create new standards.

WE DESIGN AND MANUFACTURE MACHINES THAT THEY WILL SHAPE THE FUTURE.

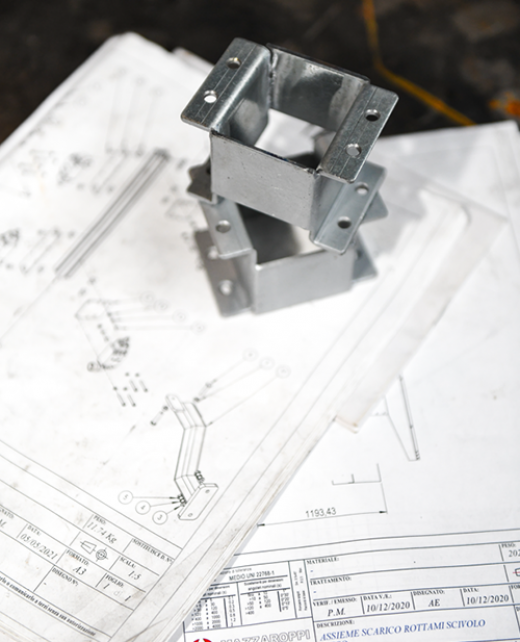

ENERGY SAVING

The energy saving approach is one of Mazzaroppi’s core values, and it is no coincidence that all of our technologies have been focused on saving energy for more than three decades.

Nowadays, energy is a precious resource, and since the future and success of our customers are

our top priority, we have studied and continue to research the best and most innovative technological solutions to ensure the best glass tempering furnaces with a consumption rate that is noticeably below average, with percentages that often leave our new customers amazed.

By purchasing a Mazzaroppi furnace you will get:

- Zero unproductive costs

- Lower initial cost for power supply systems

- Lower fixed cost for kW under contract

- Lower energy cost per production

- Zero cost for maintaining furnace temperature